In recent posts, we’ve explored how automation elevates Optical Clearing and how end‑to‑end workflows unlock publication‑ready 3D datasets.

Today, we turn the spotlight to the core technology that makes this leap possible:

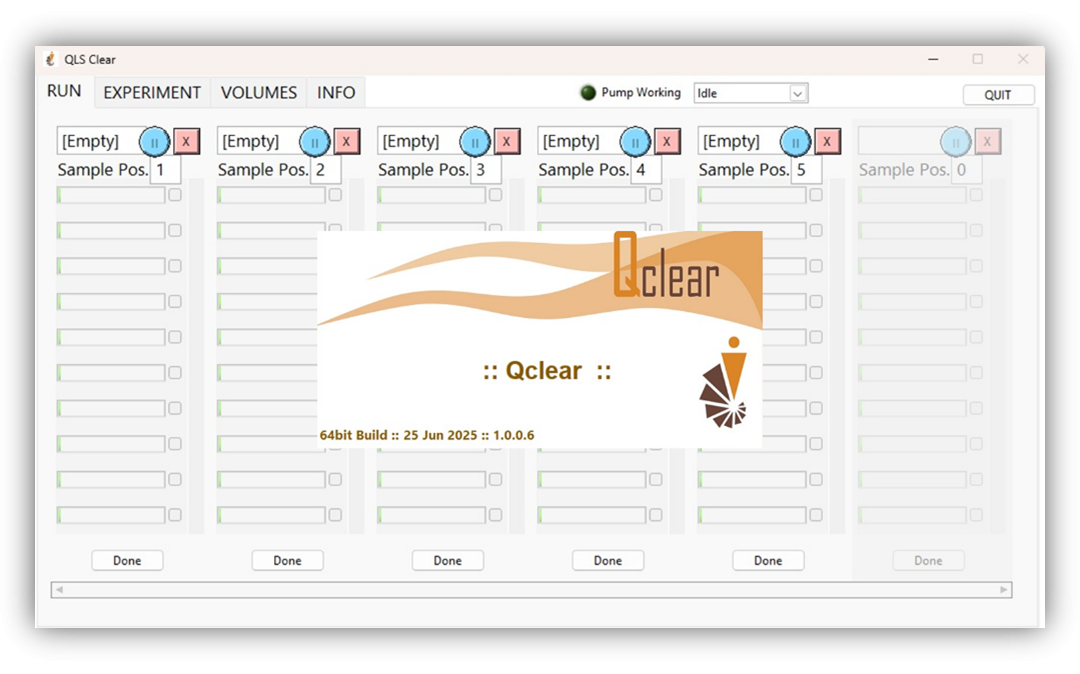

Our automated tissue‑clearing system.

Manual clearing has long been one of the most variable steps in sample preparation.

Our system was engineered precisely to eliminate that variability — delivering consistent, reproducible, and high‑quality clearing across a wide range of biological tissues.

🔹 What sets our automated system apart?

• Optimized, standardized protocols for reliable results

• Homogeneous processing, even in dense or complex tissues

• Preservation of morphology and fluorescence, essential for downstream imaging

• Full compatibility with deep immunostaining workflows

• Seamless integration with LSFM/SPIM 3D imaging

Every parameter — timing, temperature, reagent exposure, flow dynamics — is controlled with precision.

The result is a level of consistency that manual workflows simply cannot match.

🔹 Why does this matter?

Because the quality of the clearing step determines the quality of the final 3D dataset.

When clearing is automated and controlled, researchers gain:

• Deeper optical penetration

• Sharper structural detail

• More uniform signal

• Datasets that are easier to analyze and quantify

At PlaneLight, we see automation not as a convenience, but as a new standard for volumetric imaging workflows.

👉 Better clearing means better imaging — and better science.

Learn more about our automated clearing technology: